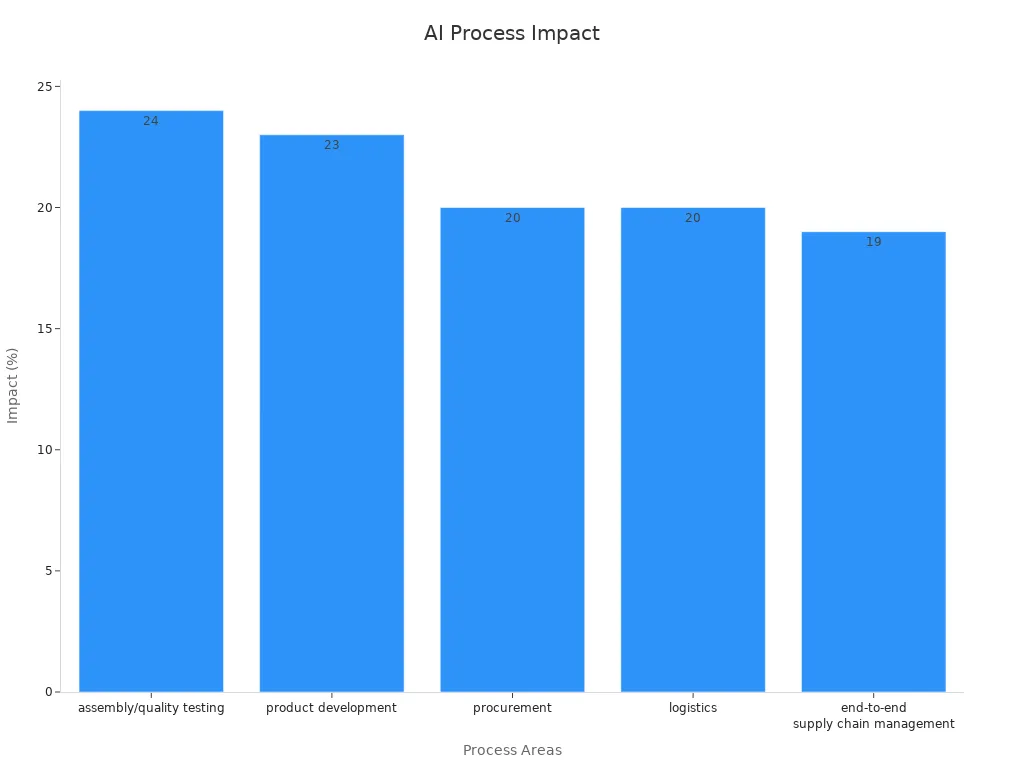

You now see ai in supply chain management drive a new era in manufacturing. With ai optimization, you boost efficiency and cut costs. You use inventory intelligence for demand forecasting, logistics, and predictive maintenance. The shift to ai in supply chain brings measurable results:

|

Metric 度规 |

Improvement with AI |

|---|---|

|

Warehouse picking accuracy |

|

|

Inventory intelligence excess stock |

15-30% reduction |

|

Inventory intelligence efficiency |

20-30% increase |

|

Inventory intelligence order speed |

30-50% increase |

Today, inventory intelligence and ai in supply chain management allow you to respond faster, reduce errors, and achieve higher efficiency.

Key Takeaways 关键的外卖

-

AI optimization boosts supply chain efficiency by improving demand forecasting, reducing inventory waste, and speeding up logistics.

-

Using AI-powered tools helps manufacturers cut costs, lower downtime, and make smarter decisions with real-time data.

-

Start small with pilot projects, train your team, and use AI solutions that fit your business to unlock lasting benefits.

AI in Supply Chain Management

AI in supply chain management changes how you approach manufacturing. You now use ai optimization to make smarter decisions, reduce costs, and improve operational efficiency. Companies like Amazon, Nestlé, and Unilever show how ai in supply chain management leads to real results. You see faster inventory movement, fewer errors, and better demand forecasting. The table below highlights some real-world examples and their measurable outcomes:

|

Company 公司 |

AI Application |

Measured Outcomes / Impact |

|---|---|---|

|

Coca-Cola, Siemens Energy |

AI-driven predictive maintenance |

Reduced downtime and maintenance costs |

|

Mars |

AI for risk management and logistics |

Lower operational costs, improved disruption resilience |

|

Katty Fashion |

Digital twins for supply chain simulation |

Optimized decisions against climate and logistics disruptions |

|

Amazon |

AI-enhanced inventory & packaging optimization |

Increased inventory movement speed by up to 75%, reduced packaging waste by over 2 million tons globally, improved delivery accuracy |

|

Nestlé |

AI-powered demand forecasting and internal communication (LLMs) |

Reduced forecasting errors by 18%, improved collaboration, better demand sensing |

|

IKEA, Coles Liquor |

AI-based inventory optimization |

Improved forecasting accuracy, reduced costs |

|

Sequoia Robotics |

Robotic inventory system |

Increased inventory identification and storage speed by 75%, reduced human effort and injury by 15%, decreased processing time by 25% |

|

Amazon (Project P.I.) |

AI for defect detection in packaging |

Automated defect detection replacing manual inspection, reducing returns due to damage or incorrect items |

These examples show how ai in supply chain management delivers higher efficiency, cost savings, and resilience.

AI-Powered Demand Forecasting

You use ai-powered demand forecasting to predict what customers want and when they want it. AI analyzes data from sales, market trends, and even weather patterns. This helps you align production with actual demand, reducing the risk of overstocking or running out of products. With predictive analytics and machine learning, you spot patterns that traditional methods miss.

AI-driven solutions in demand forecasting have led to a 20-30% reduction in safety stock and excess inventory. You also see forecasting errors drop by 18%, as seen at Nestlé. These improvements mean you can plan better, avoid backorders, and keep customers happy.

You benefit from real-time data and analytics that support dynamic production scheduling. This shift turns demand forecasting from a guesswork process into a strategic advantage. You now use inventory intelligence to make decisions that protect margins and drive growth.

Optimizing Inventory

Optimizing inventory is essential for effective inventory management. AI inventory management systems use real-time data and predictive analytics to track stock levels, automate reordering, and prevent both shortages and excess. You gain visibility into every part of your supply chain, allowing you to respond quickly to changes in demand.

Studies show that ai in supply chain management can reduce inventory levels by 20-30% and cut stockouts by 30%. Retailers have seen sell-through rates rise by 400% and stock wastage fall by 80%. You also save on shipping costs and improve operational efficiency. AI-driven solutions help you minimize waste, lower costs, and keep your supply chain running smoothly.

With inventory intelligence and real-time data, you can optimize warehouse operations, reduce travel time by 25%, and decrease operational costs by 15%. This leads to a leaner, more agile supply chain.

Logistics and Delivery

AI in logistics transforms how you move products from factories to customers. You use ai-driven solutions to analyze traffic, weather, and road conditions, finding the fastest and most fuel-efficient routes. Real-time data and analytics help you track shipments, flag delays, and improve delivery accuracy.

-

AI-powered warehouse automation speeds up picking, packing, and sorting, reducing human error and labor costs.

-

Predictive analytics in fleet maintenance helps you avoid breakdowns and cut maintenance expenses.

-

Autonomous vehicles and drones improve last-mile delivery speed and reduce failures.

Manufacturers report that ai in supply chain management increases operational efficiency, reduces costs, and boosts customer satisfaction. For example, Gatik’s autonomous trucks and Berkshire Grey’s robotic systems have made deliveries faster and more reliable. You also benefit from better risk detection and fraud prevention, making your logistic operations more secure.

Predictive Maintenance 预见性维护

Predictive maintenance uses ai and analytics to monitor equipment health and predict failures before they happen. You rely on real-time data from sensors and digital twins to spot problems early. This approach reduces downtime, cuts maintenance costs, and extends the life of your machines.

-

AI-based predictive maintenance systems help you avoid unnecessary repairs and keep production lines running.

-

Integration with digital twins allows you to optimize processes and minimize waste.

-

Collaborative robots working with humans increase output and ensure safety.

Companies like Coca-Cola and Siemens Energy have used ai in supply chain management to lower downtime and maintenance expenses. You gain operational efficiency and agility, making your manufacturing process more competitive.

Sustainability

AI in supply chain management supports your sustainability goals. You use ai optimization to reduce waste, lower emissions, and make better use of resources. Real-time data and analytics help you track your environmental impact and find ways to improve.

|

Company/Entity |

AI Contribution |

Sustainability Impact |

|---|---|---|

|

Unilever |

Significant emissions reduction in supply chain operations |

|

|

Unilever |

30% reduction in human effort via AI-powered demand forecasting |

Increased efficiency and workforce optimization |

|

Consumer Packaged Goods Companies |

Up to 20% inventory reduction using AI |

Reduced waste and optimized inventory management |

|

Walmart |

$86 million prevented in inventory waste |

Major cost savings and waste reduction |

|

DHL |

40% increase in sorting capacity through AI-driven innovations |

Enhanced logistics efficiency and sustainability |

You see how ai in supply chain management leads to less waste, better forecasting, and lower emissions. AI-driven supply chain innovations help you meet regulatory requirements and build a more sustainable future.

Implementing AI Optimization

Evaluating Solutions

You start by evaluating ai solutions that fit your business needs. Use key criteria to compare traditional and ai-driven approaches:

|

Traditional Approach |

AI-Driven Approach |

|

|---|---|---|

|

Error Detection Rate |

Moderate 温和的 |

High 高 |

|

Inspection Speed |

Slow |

Fast |

|

Operational Efficiency |

Average |

High 高 |

|

Resource Utilization |

High 高 |

Optimized |

|

Inventory Levels |

High 高 |

Optimal |

|

Demand Forecast Accuracy |

Low |

High 高 |

|

Lead Times |

Long |

Shortened |

|

Cost Efficiency 成本效率 |

Low |

High 高 |

|

Downtime (Maintenance) |

High 高 |

Low |

|

Maintenance Costs |

High 高 |

Low |

|

Equipment Lifespan |

Shorter |

Longer |

|

Failure Rates |

High 高 |

Reduced |

Track metrics like forecast accuracy, inventory turnover, and order fulfillment rates. Lenovo improved forecast accuracy by 25% and reduced surplus inventory by 20% using ai in supply chain.

Integration and Scalability

To integrate ai, map your current processes and assess your technology. Clean and standardize your data for better analytics and inventory intelligence. Start with pilot projects, then scale up. Use cloud-based ai solutions for rapid deployment, especially if you run a small or medium business. AI-powered control towers help you manage real-time data and analytics across your network.

Tip: Integrate ai with legacy ERP and WMS systems to avoid delays. Modular integration and open-source tools increase flexibility.

Best Practices

Follow these best practices for success:

-

Assess digital maturity and executive support.

-

Build a strong data foundation with governance.

-

Choose ai tools tailored to your industry.

-

Pilot test before scaling.

-

Train teams to use analytics and inventory intelligence.

Overcoming Challenges

You may face data quality issues, high costs, or resistance to change. Use rugged sensors and edge ai for real-time data in harsh environments. Foster collaboration between ai developers and domain experts. Simulation testing and explainable ai models build trust and improve operational efficiency. Address skills gaps with training and partnerships to maximize inventory intelligence and analytics.

AI optimization transforms your manufacturing supply chain. You see real gains in efficiency, cost savings, and quality. For example, predictive maintenance reduces unplanned downtime by up to 50%. Review these key improvements:

|

KPI / Metric |

AI Application Area |

Impact |

|---|---|---|

|

Inventory holding cost |

Supply Chain Optimization |

Up to 30% reduction |

|

Quality control accuracy |

AI-powered Quality Control |

Over 97% accuracy |

|

Demand forecasting accuracy |

Supply Chain Optimization |

Exceeds 85% |

Start with pilot projects, train your teams, and measure results to unlock these benefits.

FAQ 常见问题解答

What is the main benefit of using AI optimization in supply chain management?

You gain higher supply chain efficiency. AI optimization helps you reduce costs, improve forecasting, and make better decisions using real-time data and analytics.

How does AI-powered demand forecasting improve inventory management systems?

AI-powered demand forecasting uses predictive analytics and real-time data. You can align inventory intelligence with actual demand. This leads to more effective inventory management and less waste.

Can AI-driven solutions help with logistics and delivery challenges?

Yes. AI-driven solutions in logistics use data and analytics to optimize routes, predict delays, and automate tasks. You see faster deliveries and improved operational efficiency in your logistic operations.